POP2045

Polyester polyols Chemical Structure Composition

Production

Polyester polyols are typically produced by the condensation reaction of a glycol with a dicarboxylic acid.

Main acids utilized are Adipic, Phtalic anhydride, Isophtalic, Terephtalic, Succinic, Sebacic

Main glycols utilized are MEG, DEG, BDO, HDO, NPG, TMP.

There are two different types of polyester polyols:

Standard polyester polyols are typically quite viscous because of the nature of the reaction between the glycol and the dicarboxylic acid. The molecular weight distribution is relatively broad.

Higher performance polyesters such as polycaprolactones are formed by ring opening of a heterocycle ring (caprolactone monomer). The polyol created has a low polydispersity. Polycaprolactones have significantly lower viscosities, enhanced mechanical properties, as well as enhanced low temperature and high temperature performance properties.

Polyols contain reactive hydroxyl (OH) groups which react with isocyanate (NCO) groups on isocyanates to form polyurethane.

Polyol polyester provide a better adhesion while improving abrasion resistance and overall hardness.

Key Parameters:

The hydroxyl number (OH): is the measure of the hydroxyl group content of gram of polyol.

Hydroxyl value (OH value): is measured by titrating a known mass of polyol against potassium hydroxide (KOH), and is expressed as mg KOH/g.

Lower hydroxyl values indicates lower hydroxyl content and a higher molecular weight for the overall polyol.

OH equivalent weight: is the number of grams of a given product that contains one equivalent of hydroxyl groups (NCO). Equivalent weight = 56100/OH

Molecular weight: is determined by multiplying the equivalent weight by the polyol functionality

The functionality: of the polyol refers to the number of OH groups per molecule.

Increasing the number of OH groups results in greater crosslinking. Greater crosslinking yields stiffer, harder products with enhanced chemical and thermal resistance. Polyols that contain 2 hydroxyl groups are called diols, polyols with 3 functional groups are called triols, polyol groups with 4 hydroxyl groups are called tetrols.

USES

PUR fusion adhesive : PUR adhesive application improve adhesion strength, resistance to deformation, bonding profiles of substrates and modify the open time.

Flexible Packaging adhesive: polyester polyols deliver improved hydrolytic stability under acid and base conditions, flexibility, good pot life, and adhesion on substrate

Urethane Coating Resins: polyester polyols can be further compounded to radiation curable oligomers or polyurethane dispersions, offering hardness, flexibility, solvent resistance, and/or weatherability, depending on the grade.

Acrylate polymerization

Automotive – Noise, Vibration, Harshness (NVH)

Non-foaming emulsions

Fiberglass reinforced backing material

Manufactured housing adhesive

High quality polyurethane sealants – Sealer insulation (one-component foam)

Polyurethane Elastomers and Thermoplastic Polyurethanes (TPU): aliphatic polyesters contribute to excellent abrasion and tear resistance. They provide as well strong load bearing thus are commonly used in wheels, industrial and printing rolls as well as in mining equipment.

Rollers

Conveyor belts

Thermal break

Coating Adhesive Sealant Elastomer (CASE): High polyester polyols for CASE applications based on dimer fatty acids provide hydrophobicity, flexibility, elongation to the final polyurethane

Flexible PU Foam

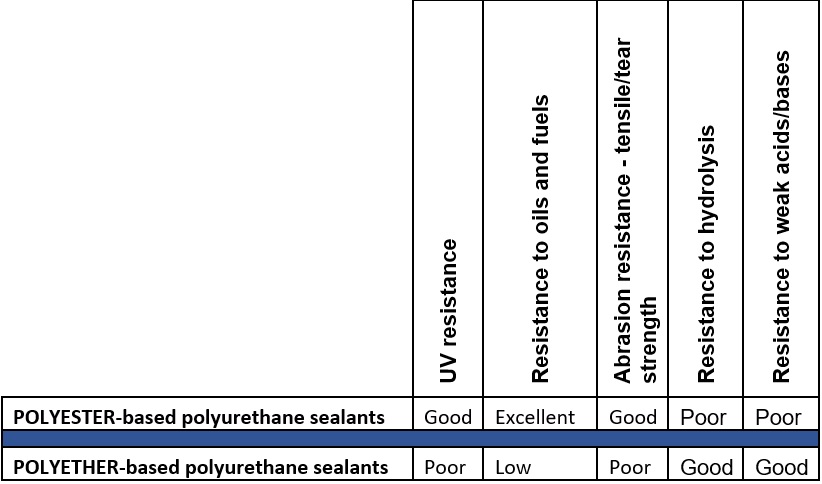

POLYESTER Polyol vs POLYETHER Polyol products

To thrive in an industry that has an expansive global presence, it is important to cultivate long-lasting and fullfilling relationships with our suppliers and customers based on mutual understanding and responsibility.